- Schedule. Mon - Sat 10.00 - 18.00

SS Ultra-Flexible Metal hoses

Ultra-flexible metal hoses, crafted from stainless steel, boast exceptional durability. These hoses are close pitch corrugated hose, than standard types, rendering them remarkably flexible. Available in both braided and non-braided variants, they can be customized with fittings at the ends to meet customer requirements. Manufactured in accordance with EN-10380 standards, ultra-flexible metal hoses serve a wide range of industrial applications.

ADVANTAGES:

- Long Product Life: These hoses are durable and have a prolonged lifespan.

- Suitable for Moving Parts: Their flexibility makes them ideal for use in machinery with moving components.

- High Pressure and Temperature Resistance: They can handle challenging operating conditions.

- Ease of Assembly: Simple installation process.

- Hygienic: Suitable for applications where cleanliness is crucial.

APPLICATIONS:

- Machinery Industry: Used in various machinery applications.

- Iron and Steel Industry: Supporting processes within iron and steel factories.

- Pharmaceutical Industry: Meeting specific requirements in pharmaceutical facilities.

- Chemical Industry: Handling chemical substances.

- Hot & Cold Water Pipelines: Efficiently transporting water.

- Steam Pipelines: Handling steam distribution.

DESIGN SPECIFICATIONS:

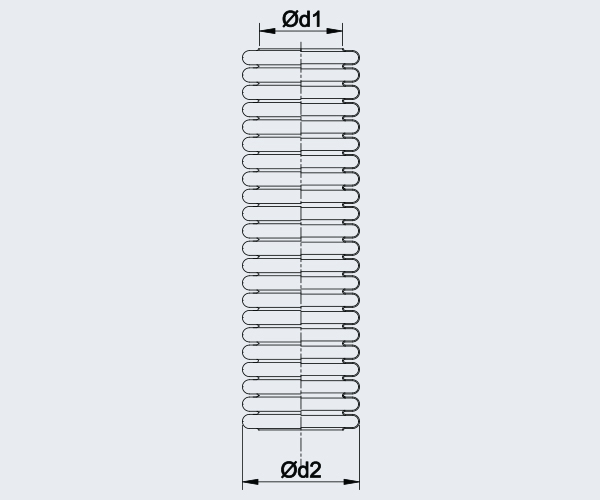

- Without Braid

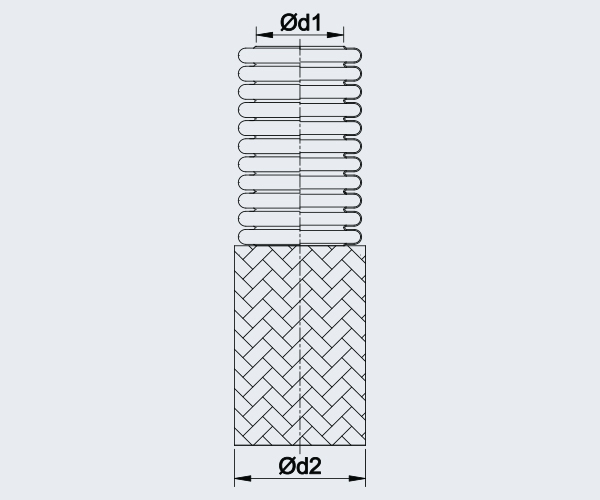

- With Braid

- Hose Material: 304L, 316L, 321

- Braid Material: 304L, 316L

- Working Pressure: 0-10kg/cm²

- Sizes: DN6-DN50

| DN | d1 | d2 | Tolerance | “Bend Radius With Wire Braiding TYPE 1 AND 2 (BRAIDED)” | “Bend Radius Without Wire Braiding TYPE 3 (UNBRAIDED)” | Working Pressure | |

| mm | inch | mm | mm | mm | mm | mm | mm |

| 6 | 1/4″ | 6,3 | 9,6 | ± 0,2 | 25 | 12 | 10 |

| 8 | 5/16″ | 8.2 | 12.2 | ± 0,2 | 32 | 16 | 10 |

| 10 | 3/8″ | 10.3 | 14.2 | ± 0,2 | 38 | 20 | 8 |

| 12 | 1/2” | 12.1 | 16.7 | ± 0,2 | 45 | 25 | 8 |

| 16 | 5/8” | 16.2 | 21.6 | ± 0,2 | 58 | 25 | 8 |

| 20 | 3/4″ | 20.3 | 26.8 | ± 0,2 | 70 | 30 | 6 |

| 25 | 1″ | 25.3 | 32.3 | ± 0,3 | 85 | 45 | 6 |

| 32 | 11/4″ | 34.3 | 41.1 | ± 0,3 | 105 | 60 | 2.5 |

| 40 | 11/2″ | 40.2 | 49.8 | ± 0,3 | 130 | 80 | 2.5 |

| 50 | 2″ | 50.3 | 60.4 | ± 0,4 | 160 | 100 | 1.6 |

| DN | d1 | d2 | Tolerance | “Bend Radius With Wire Braiding TYPE 1 AND 2 (BRAIDED)” | “Bend Radius Without Wire Braiding TYPE 3 (UNBRAIDED)” | Pressure at ambient temperature | ||

| Working Pressure | Test Pressure | |||||||

| mm | inch | mm | mm | mm | mm | mm | Kg /cm2 | Kg /cm2 |

| 6 | 1/4″ | 6.3 | 10.8 | ± 0,2 | 110 | 140 | 120 | 180 |

| 8 | 5/16″ | 8.2 | 13.7 | ± 0,2 | 130 | 165 | 100 | 150 |

| 10 | 3/8″ | 10.3 | 15.7 | ± 0,2 | 150 | 190 | 90 | 135 |

| 12 | 1/2” | 12.1 | 18.1 | ± 0,2 | 165 | 210 | 80 | 120 |

| 16 | 5/8” | 16.2 | 23.2 | ± 0,2 | 195 | 250 | 70 | 105 |

| 20 | 3/4″ | 20.3 | 28.4 | ± 0,2 | 225 | 285 | 64 | 96 |

| 25 | 1″ | 25.3 | 34.4 | ± 0,3 | 260 | 325 | 50 | 75 |

| 32 | 11/4″ | 34.3 | 43.2 | ± 0,3 | 300 | 380 | 40 | 60 |

| 40 | 11/2″ | 40.2 | 52.2 | ± 0,3 | 340 | 430 | 35 | 52.5 |

| 50 | 2″ | 50.3 | 62.7 | ± 0,4 | 390 | 490 | 30 | 45 |