- Schedule. Mon - Sat 10.00 - 18.00

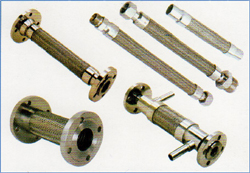

Ss Hose And Fittings Assembly

STAINLESS STEEL CORRUGATED FLEXIBLE HOSES

A full range of metallic flexible hoses & hose assemblies are manufactured in austenitic steel are AISI 304, 321, 316 L conforming to international quality standards.

ADVANTAGES OF FLEXIBLE METAL HOS

- Suitable for wide temperature range (-200°C to + 700°C)

- Compensates for thermal expansion contraction in the piping system

- High physical strength

- Fire resistant. Longer life. Moisture resistant

- Good corrosion, characteristics

- Resistant to abrasion, penetration and damage

- Connects misaligned rigid piping absorbs or dampens vibration and similar equipments..

- A flexible and quick option for rigid piping in difficult locations

HOSE

Stainless steel corrugated flexible hoses are made from 6mm (1/4") to 300mm (12") in side diameter. The annular corrugated hose body provides the flexibility and pressure tight core of the assembly. Braiding in high tensile stainless steel AISI 304 wire.

MODES OF MOVEMENTS

- STATIC INSTALLATIO: NS Where the flexible hose is used to connect misaligned pipes and remain in static position.

- OCCASIONAL FLEXING: Where the hose is required to flex occasionally, such as manually operated equipment.

- CONSTANT FLEXING: When the hose is required to flex continuously, usually In moving machinery.

- VIBRATION: High frequency, low amplitude movement e.g. On a compressor.

QUALITY CONTROL

Every single hose assembly is tested hydraulically at 1.5 times working pressure before dispatch. Pneumatic testing is also carried out whenever necessary. All raw material used to manufacture of hoses, braiding and end connection undergo rigid inspection to ensure highest quality standards

| TECHNICAL DATA | ||||||||

|---|---|---|---|---|---|---|---|---|

| NORMAL BORE N.B. mm |

MINIMUM BEND RADIUS | WITHOUT BRAID | SINGLE BRAID | DOUBLE BRAID | ||||

| STATIC mm |

FLEXING mm |

MAX Working Pressure Kg/cm2 |

TEST Pressure Kg/cm2 |

MAX Working Pressure Kg/cm2 |

TEST Pressure Kg/cm2 |

MAX Working Pressure Kg/cm2 |

TEST Pressure Kg/cm2 |

|

| 6 | 25 | 100 | 4 | 6 | 100 | 150 | 160 | 240 |

| 10 | 40 | 150 | 4 | 6 | 90 | 135 | 144 | 216 |

| 12 | 50 | 200 | 3 | 4.5 | 80 | 120 | 128 | 192 |

| 16 | 50 | 200 | 3 | 4.5 | 70 | 105 | 112 | 168 |

| 20 | 70 | 200 | 2 | 3 | 64 | 96 | 102 | 153 |

| 25 | 90 | 200 | 2 | 3 | 50 | 75 | 80 | 120 |

| 32 | 110 | 250 | 1.5 | 2.3 | 40 | 60 | 64 | 96 |

| 40 | 130 | 250 | 1.5 | 2.3 | 30 | 45 | 48 | 72 |

| 50 | 175 | 350 | 1.0 | 1.5 | 28 | 42 | 44 | 66 |

| 65 | 200 | 410 | 1.0 | 1.5 | 24 | 36 | 38 | 57 |

| 80 | 205 | 450 | 1.0 | 1.5 | 18 | 27 | 28 | 42 |

| 100 | 230 | 560 | 0.8 | 1.2 | 16 | 24 | 26 | 39 |