- Schedule. Mon - Sat 10.00 - 18.00

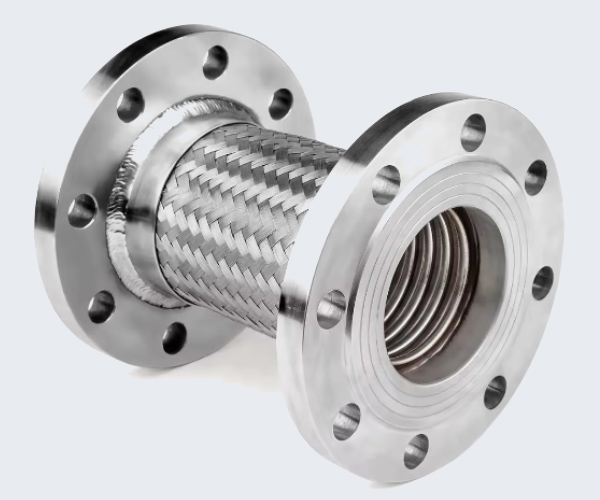

SS Large Diameter Flexible Metal Hoses

Large diameter hoses, akin to industrial flexible metal hoses, are produced in Size From 21/2″ to 12″ (65 mm ID to 300mm ID). They are employed for gas and liquid transfer in extensive industrial facilities, such as iron and steel factories, cement plants, fuel oil production and storage sites, and gas distribution facilities. These hoses are preferred for their ease of installation in moving parts.

ADVANTAGES:

- Long Product Life: These hoses are durable and have a prolonged lifespan.

- Suitable for Moving Parts: Their flexibility makes them ideal for use in machinery with moving components.

- High Pressure and Temperature Resistance: They can handle challenging operating conditions.

- Ease of Assembly: Simple installation process.

- Hygienic: Suitable for applications where cleanliness is crucial.

- Customizable Lengths: Your company’s ability to manufacture single pieces exceeding 100 meters is impressive.

APPLICATIONS:

- Hydraulic Systems: Used for fluid transfer in hydraulic machinery.

- High Pressure Pumps: Handling pressurized liquids.

- Gas Distribution Lines: Efficiently transporting gasses.

- Machinery Industry: Supporting various industrial processes.

- Chemical Industry: Handling chemical substances.

DESIGN SPECIFICATIONS:

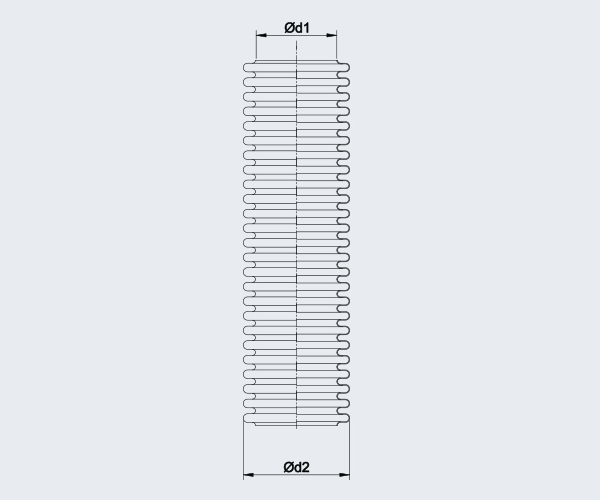

- Without Braid

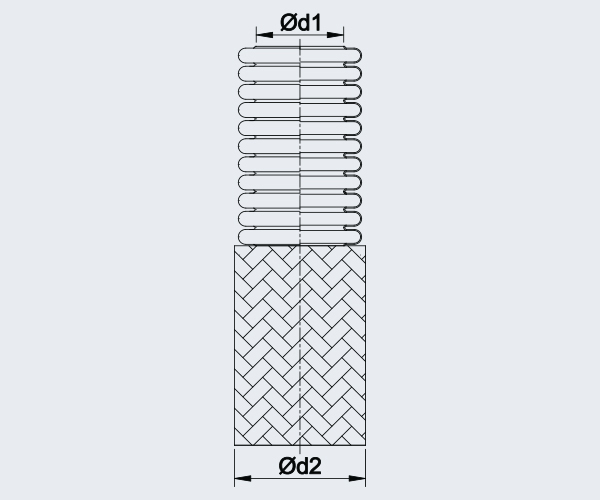

- With Braid Hose Material: 304L, 316L, 321 Braid

- Material: 304L, 316L

- Working Pressure: 0-1.2kg/cm² for only Hose

- Working Pressure: 0-24kg/cm² for only Hose with Brading

- Sizes: DN65 to Dn300 (2½” NB to 12″NB)

| DN | d1 | d2 | Tolerance | “Bend Radius With Wire Braiding TYPE 1 AND 2 (BRAIDED)” | “Bend Radius Without Wire Braiding TYPE 3 (UNBRAIDED)” | Working Pressure | |

| mm | inch | mm | mm | mm | mm | mm | mm |

| 65 | 21/2″ | 65.8 | 81 | ±1,0 | 200 | 115 | 1.2 |

| 80 | 3″ | 80.9 | 95 | ±1,0 | 240 | 130 | 1 |

| 100 | 4″ | 100.2 | 117 | ± 1,0 | 290 | 160 | 1.4 |

| 125 | 5″ | 125.8 | 150 | ± 1,2 | 350 | – | 0.8 |

| 150 | 6″ | 150.8 | 175 | ± 1,5 | 400 | – | 0.6 |

| 200 | 8″ | 197 | 225 | ± 2,0 | 520 | – | 0.4 |

| 250 | 10″ | 250.4 | 278 | ± 2,0 | 620 | – | 0.4 |

| 300 | 12″ | 300.2 | 336 | ± 2,0 | 720 | – | 0.4 |

| DN | d1 | d2 | Tolerance | “Bend Radius With Wire Braiding TYPE 1 AND 2 (BRAIDED)” | “Bend Radius Without Wire Braiding TYPE 3 (UNBRAIDED)” | Pressure at ambient temperature | ||

| Working Pressure | Test Pressure | |||||||

| mm | inch | mm | mm | mm | mm | mm | Kg /cm2 | Kg /cm2 |

| 65 | 21/2″ | 65.8 | 81.1 | ±1,0 | 460 | 580 | 24 | 36 |

| 80 | 3″ | 98.2 | ±1,0 | ±1,0 | 660 | 800 | 18 | 27 |

| 100 | 4″ | 100.2 | 119.5 | ±1,0 | 750 | 1000 | 16 | 24 |

| 125 | 5″ | 125.8 | 148 | ± 1,2 | 1000 | 1250 | 14 | 21 |

| 150 | 6″ | 150 | 173.5 | ± 1,5 | 1250 | 1550 | 10 | 15 |

| 200 | 8″ | 197 | 225 | ± 2,0 | 1600 | 2000 | 8 | 12 |

| 250 | 10″ | 250.4 | 278 | ± 2,0 | 2000 | 2500 | 7 | 10.5 |

| 300 | 12″ | 300.2 | 336 | ± 2,0 | 2400 | 3000 | 6 | 9 |